Case Study: Improving Productivity by Making Metrics Visible at Apex Manufacturing

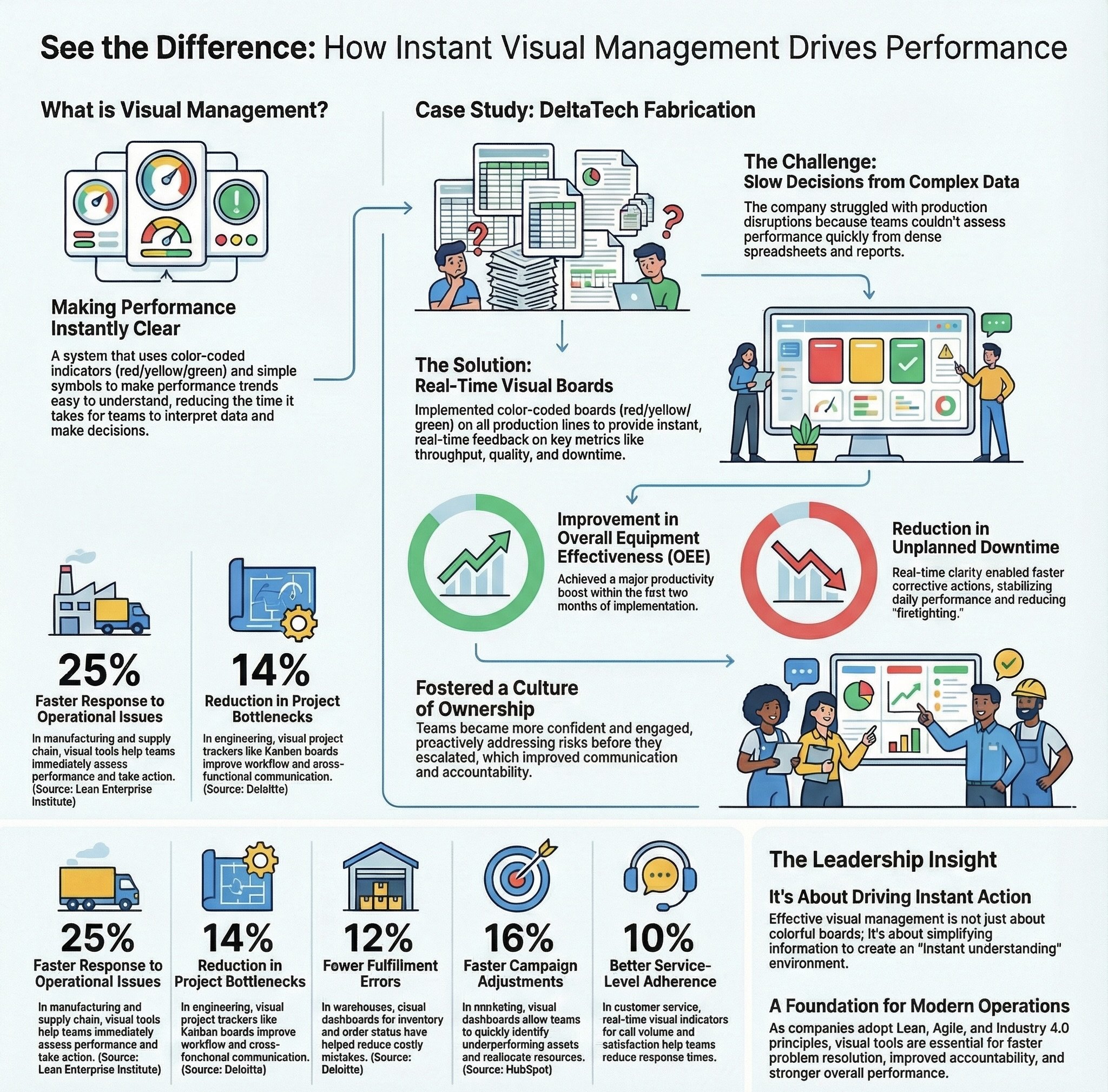

Apex Manufacturing, a mid-sized producer of industrial components, was struggling with stagnant productivity levels and a lack of engagement from frontline teams. Although the company tracked key performance indicators (KPIs) such as throughput, downtime, and quality defects, this data was typically stored in spreadsheets shared via email or reviewed only in weekly management meetings. As a result, employees on the shop floor had little visibility into daily performance trends, and accountability remained limited to supervisors and managers.

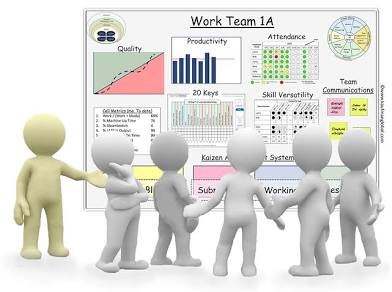

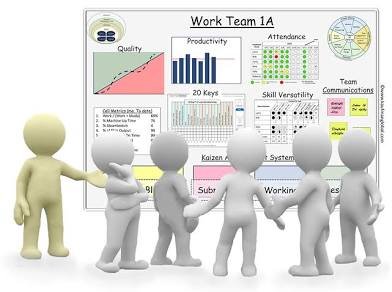

In an effort to create a more transparent and performance-driven environment, Apex implemented a new strategy: make metrics visible to everyone. They installed digital dashboards at key points across the production floor and in break areas, displaying live feeds of critical KPIs updated in real-time from the company’s production systems. Additionally, whiteboards were introduced for team leaders to track and discuss daily and shift-level performance. Employees were encouraged to participate in reviewing results during shift huddles, and action plans were created collaboratively to address any variances.

Within three months of implementation, Apex saw a noticeable shift in both employee engagement and operational performance. Teams became more proactive in addressing production bottlenecks, leading to a 15% reduction in downtime and a 10% increase in throughput. Quality defects per shift also dropped by 8%, as employees were now more aware of how their actions impacted overall quality performance. The visibility of metrics encouraged peer accountability and fostered a sense of ownership at every level.

Beyond the numbers, the cultural shift was evident. Employees expressed a stronger connection to company goals, with many reporting that the visual tracking tools made them feel more empowered and valued. By moving KPIs out of spreadsheets and onto visible boards and dashboards, Apex Manufacturing built a culture of continuous improvement and data-driven decision-making, setting the stage for sustained productivity gains.