One of the cornerstones of MOS is consistent execution. Define and document standard work processes clearly. Train teams on them and use them as a baseline for continuous improvement. Without standards, you can’t measure or manage effectively.

Establish a Cadence That Sticks (Part 3 of 3)

Industry Trends: Driving Productivity through a Consistent Cadence

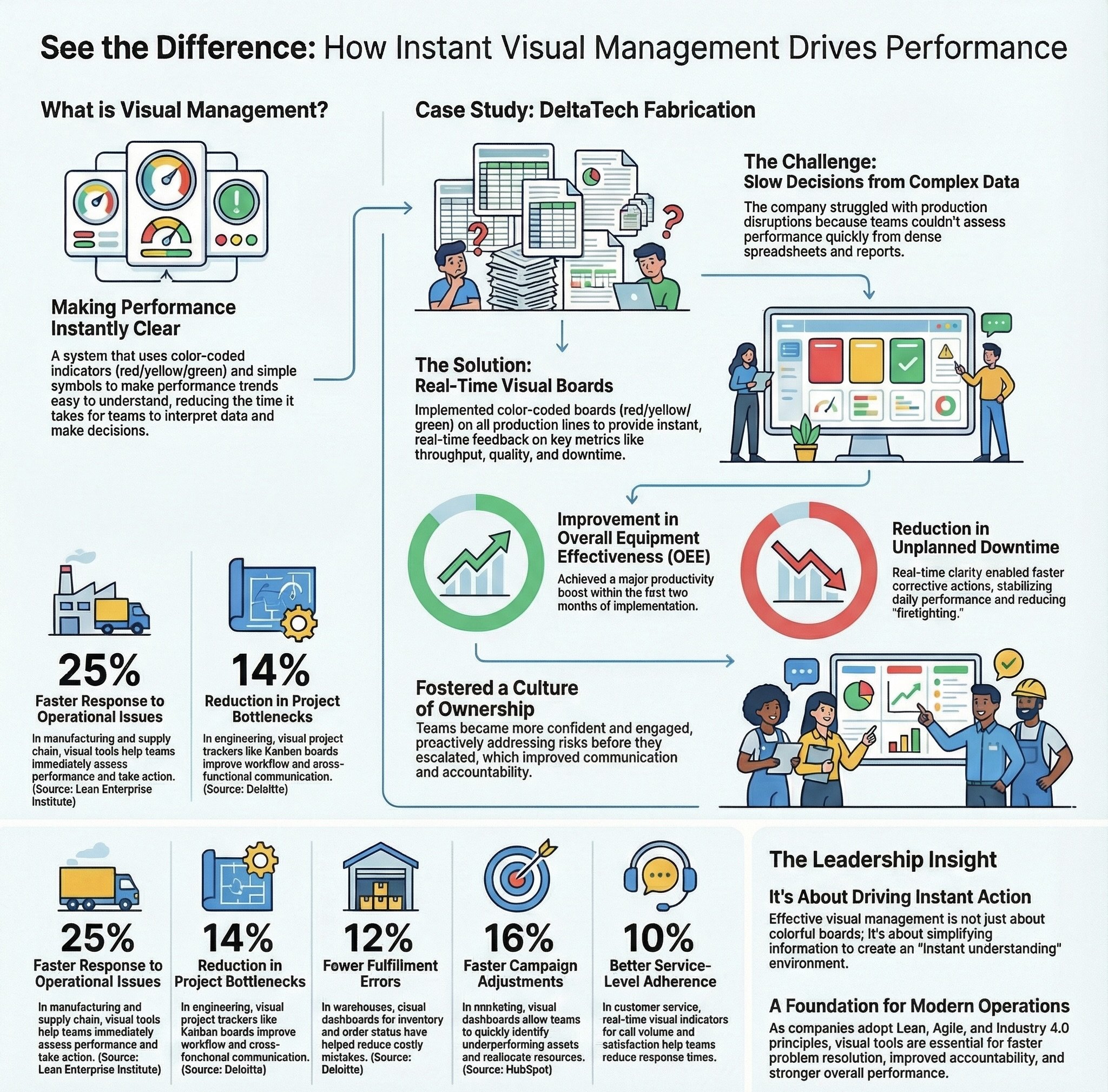

In industries like manufacturing, engineering, supply chain, and services, leaders are increasingly recognizing that operational cadence is critical for driving consistency and productivity. According to a study by PwC, companies that implement structured rhythms, such as daily huddles and weekly planning cycles, are 24% more likely to achieve their operational targets. In manufacturing and warehousing, where variability can disrupt flow and efficiency, establishing a steady Management Operating System (MOS) cadence reduces firefighting and promotes proactive problem-solving. Organizations are moving away from ad-hoc meetings toward disciplined daily and weekly routines that ensure alignment and create predictability across teams.

Engineering and supply chain leaders are applying similar principles to improve project execution and process reliability. A report from Deloitte found that engineering teams using a formal cadence, including weekly design reviews and sprint retrospectives, shortened project lead times by an average of 15%. In the supply chain sector, consistent operational rhythms—such as daily logistics stand-ups and weekly inventory reviews—have helped reduce fulfillment errors and stockouts by as much as 18%. Leadership is realizing that when teams know when and how issues will be addressed, they are less likely to operate in crisis mode and more likely to make decisions based on data and trends.

Marketing and service industries are also embracing cadence-driven frameworks to improve execution and customer satisfaction. HubSpot reports that marketing teams with formalized weekly performance reviews and monthly campaign retrospectives experience a 19% higher success rate in achieving their KPIs compared to teams without a clear cadence. In services, companies that conduct regular client check-ins and internal team debriefs reduce customer churn by up to 10%. The key is consistency—when teams engage in regular performance conversations, they foster accountability, improve communication, and create space for continuous improvement.

Across sectors, the trend is clear: leaders are embedding cadence as a core element of their MOS to build operational resilience and drive performance. The rise of digital tools and collaborative platforms has made it easier to standardize and scale these rhythms across locations and departments. Whether it’s daily tiered huddles on a production floor or weekly planning sessions in a marketing agency, organizations with a cadence that sticks are better positioned to prevent surprises, respond quickly to challenges, and sustain high levels of productivity over time.

Establish a Cadence That Sticks (Part 2 of 3)

Case Study: Driving Productivity through a Consistent Cadence at Titan Components

Titan Components, a manufacturer of precision-machined parts, was facing inconsistent production performance marked by missed deadlines, reactive firefighting, and poor cross-functional communication. While the company had elements of a Management Operating System (MOS) in place—such as team meetings and performance reviews—these were irregular and varied widely between departments. Without a consistent cadence, production teams struggled to anticipate issues, and leadership found it difficult to align daily operations with strategic objectives.

To address these challenges, Titan Components launched an initiative to establish a structured and repeatable cadence across all levels of the organization. This included implementing daily shift huddles for frontline teams, weekly production planning meetings for supervisors, and monthly performance reviews with senior management. Each meeting followed a standardized agenda focused on KPIs, problem-solving, and forward-looking actions. Managers were trained to facilitate these sessions effectively, ensuring discussions stayed focused and outcomes were documented and tracked.

The impact was immediate and significant. Within two months, Titan saw a 20% improvement in schedule adherence and a 12% increase in overall equipment effectiveness (OEE). Issues that previously escalated unnoticed were now identified and addressed early through daily huddles, while weekly planning meetings helped teams proactively allocate resources and manage capacity. Monthly reviews enabled senior leadership to identify recurring patterns and systemic issues, leading to data-driven improvements in processes and resource planning.

More importantly, the company experienced a cultural transformation. Employees across all levels reported feeling more connected to company goals and more confident in their ability to manage daily challenges. The predictable cadence created operational discipline and reduced last-minute surprises, contributing to a more stable and productive environment. By embedding a consistent MOS rhythm, Titan Components not only enhanced its operational predictability but also laid the foundation for sustainable productivity gains and continuous improvement.

Establish a Cadence That Sticks (Part 1 of 3)

MOS is about rhythm. Whether it’s daily huddles, weekly planning, or monthly reviews, make sure every team level has a defined and repeatable cadence. A consistent MOS cycle prevents surprises and creates operational predictability.

WASHINGTON STATE COMMITS TO RUNNING ENTIRELY ON CLEAN ENERGY BY 2045

If you’re depressed by the climate politics of Washington, D.C., may I suggest checking out the other Washington. On Thursday, the state legislature officially passed one of the most ambitious clean energy bills in the nation.

ENTREPRENEURS RESHAPING THE FUTURE

Move over, United Nations: it's time for entrepreneurs to save the planet

THE CORRELATION BETWEEN MLM SUCCESS AND MENTORSHIP

There was a panel discussion that looked into the way that 3 different large organizations have implemented mentorship programs.

LED SCALE-UP

Lighting accounts for nearly 6% of global CO2 greenhouse gas emissions. Light emitting diode (LED) technology is capable of achieving up to 50-70% energy savings. Wider adoption of such energy efficient lighting can provide a significant reduction in global emissions.

WHATEVER HAPPENED TO JIMMY CARTER'S SOLAR PANELS: THE SEQUEL

They are perhaps the most famous solar panels ever made, installed on the roof of the White House by President Jimmy Carter.

This Texas district is getting students to become active learners, problem solvers, and STEM advocates